ERPNext’s powerful manufacturing capabilities make it suitable for any discrete or process manufacturing use case. ERPNext also supports complex engineer to order workflows.

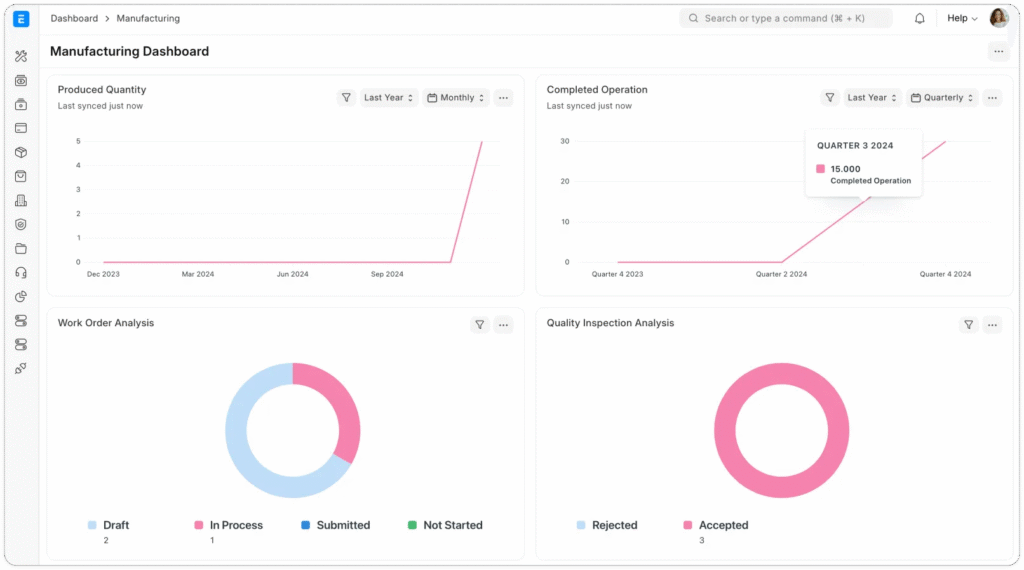

With ERPNext, all your business information is centralized in one place and seamlessly connected. Imagine a system where delivering to your customers automatically updates the corresponding Sales Order status, ensuring you always know what’s completed and what’s pending. A single connected system helps you make sense of your operations, even in a visual-way through Dashboards.

Textile Product Manufacturers

Food manufacturing is complex, be it dealing with quality assurance checks, constantly changing food prices, eco-friendly packaging, or the competition to keep up.

Increase productivity, manage your supply chain smoothly and get your food to distributors and consumers faster with ERPNext. It’s packed with integrated inventory to manage your manufacturing, purchases, sales, suppliers, and customers — all in one software.

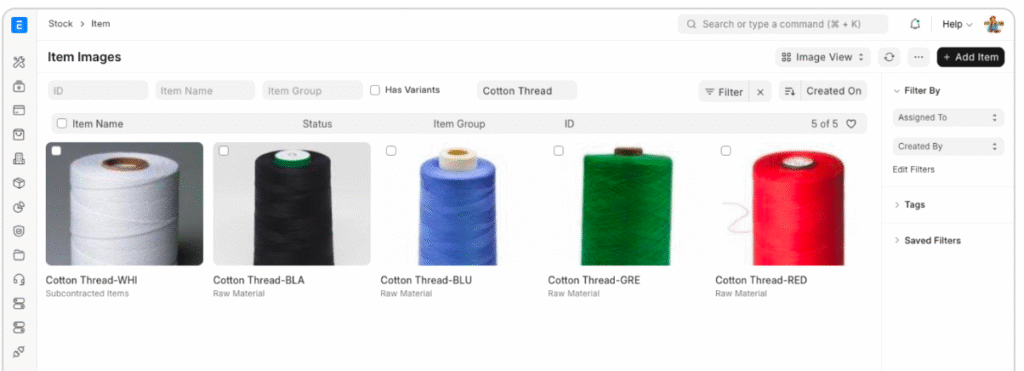

Item Variants

Textile manufacturers have to manage thousands of product permutations, such as color or length. In ERPNext, the primary item is stored as an item template, and each of the variations is stored as an item variant.

Smarter Workflows to get more done in less time

Multi-Level Approval: Enable seamless collaboration with built-in accountability using easy-to-configure multi-level approval systems. Whether it’s your return merchandise authorization (R.M.A.) process or payment workflows, ensure every step is clear, controlled, and efficient

Automated Notifications: Avoid missing important events, set up automated notifications. ERPNext can even send automated payment follow-ups.

Quality control: Ensure your products meet industry regulations and quality standards without additional manual effort. ERPNext automates compliance documentation, quality control checks, and batch traceability, making ISO and other regulatory audits effortless.

Customer and supplier relations: Make smarter procurement decisions with real-time vendor and supplier performance analytics. Track key metrics such as on-time delivery rates and defect percentages to optimize your supply chain. Provide customers with a self-service portal for instant order tracking, reducing delays and improving satisfaction.

Production floor optimisation: Improve efficiency by tracking employee skills, assigning jobs intelligently, and reducing downtime. ERPNext’s integrated workforce management tools help allocate the right personnel for each task, enhancing overall productivity. IoT integration (not in-built) allows real-time shop floor updates, eliminating paperwork and streamlining operations.